INTRODUCING THE LATEST IN HYDROCARBON DECONTAMINATION TECHNOLOGIES

TC-500 RAPID RESPONSE SYSTEM

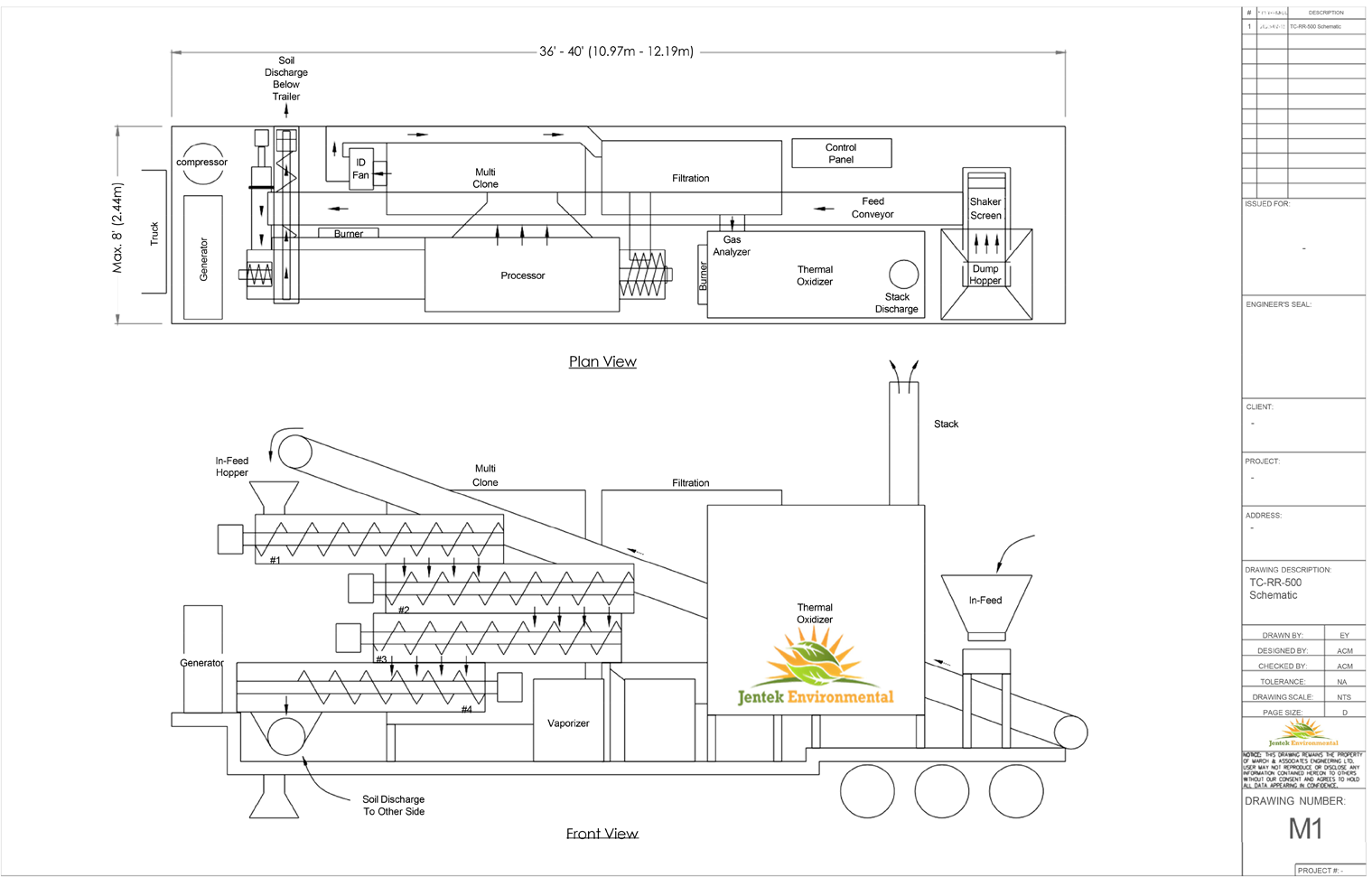

INDUSTRY NEED: Jentek has identified a growing need for a smaller, single trailer, mobile remediation system with the feed system onboard that can react quickly to oil spills, storage tank overflows and smaller contaminated site cleanup. Not only in Canada and the US, but also in Europe and the Middle East where insurrections have resulted in oil line and other breakage, a method of getting to the problem quickly is a definite need. Jentek’s TC-500 system has been designed to provide a solution for this need and it is capable of being taken to a site, set up in less than 2 hours, and can process from 4 – 7 tons/hour of hydrocarbon (oil) contamination.

SYSTEM TECHNOLOGY: Based on the forerunner systems Jentek has been building for almost 30 years, these systems are compact, reliable, endurable and very versatile, plus they are inexpensive to own and operate. (See Detailed Specification Data for particulars). They are Low Temperature Thermal Desorption (LTTD) systems that separate the hydrocarbons from the soil thermally, discharging clean soil to be used immediately with no damage to the soil organics, and destroying the contaminants in a Thermal Oxidizer to get rid of them once and for all. Air emissions from the stack meet or exceed all jurisdictional air regulations worldwide.

FEATURES: The TC-500 can operate up to 22 hours in a day continuously with only a 2 hour window for basic maintenance. It has a continuous air emissions testing system that can be fed back to the Control Panel for automatic emissions adjusting. The TC-500 has an onboard 3-phase diesel generator for remote operation and the burners can be operated on propane, LNG or diesel.

THERMO-CLEAN 3000 Series MOBILE SOIL REMEDIATION SYSTEMS

-

Cascading Portable soil remediation systems mounted on single trailer,

48′ X 8″ X 13.5′ with separate feed system trailer. -

Capable of up to 15 tons/hour throughput and soil moisture of 12%

-

Removes up to 99% Hydrocarbon contaminants

-

Effective on contaminant levels to 44,000 mg/kg (PPM) and up to C-40

-

Small footprint and low operating costs

-

Multi-fuel capability for remote operation

-

Meets all emission standards

ThermoClean TC-3000 Video

THERMO-CLEAN Dual Processor

- Jentek is developing a Dual Processor adaptation for next generation machines utilizing the claims of the new US Patent secured by Mr. Wilford in April, 2012.

THERMO-CLEAN Dual Trailer Model For larger, stationary long-term projects

- Two (2) trailer system with equipment on each trailer but operating in tandem, (2 X 40′ X 8″ X 13.5′) with separate feed system trailer. Will have shared equipment on each trailer so must be operated together.

- Capable of up to 30 tons/ hour throughput and soil moisture of 12%

- Removes up to 99% Hydrocarbon contaminants

- Effective on contaminant levels to 44,000 mg/kg (PPM) and up to C-40

- What is gained in throughput is somewhat offset in versatility as both trailers must be operated in tandem

- Multi-fuel capability for remote operation

- Meets all emission standards

Typical site layout drawing of a 2-skid or 2-trailer unit capable of cleaning up to 30T per hour.

-

Shaker Screen removes all rocks and waste material over 2 inches (50mm) in diameter

-

Metres the input to the conveyer belt to provide a constant stream to the Processor

-

Conveyer belt carries the contaminated soil to the input auger(s)

-

Can be used in conjunction with a trommel to reduce moisture content (optional)

-

Several variations available including folding models

-

Can be towed to site with a lighter truck

-

Operated and controlled by TC-3000 control panel with independent adjustments